A slotting cutter holder is a multifunctional, high-precision tool holder designed to meet the needs of complex groove machining. It is widely used in various fields such as mechanical processing, mold manufacturing, and automotive parts production. Its most notable feature is its ability to hold a wide range of milling tools, including slotting saws, slitting saws, gear cutters, and side milling cutters.

Applications

The primary purpose of the slotting cutter holder is to assist machine tools in the precise machining of grooves on workpieces. It ensures accurate cutting by securely holding various cutting tools, which is essential when machining grooves of different shapes and depths. For example, in part processing, the slotting cutter holder can be used to cut key slots on shaft parts, ensuring a tight fit with other components. In mold manufacturing, it is suitable for machining complex mold features such as T-slots and V-slots. Such precise machining not only enhances production efficiency but also ensures the durability and accuracy of the mold.

Additionally, gear manufacturing is one of the key applications for slotting cutter holders. Gear cutters are specialized for cutting gear teeth, and the holder's ability to securely hold the tool ensures that the gear milling cutter does not shift or vibrate during high-speed operation. This enables precise gear machining, which is crucial in industries such as automotive, machinery, and aerospace, where high precision in parts is essential.

Working Principle

The slotting cutter holder operates by firmly clamping the cutting tool in the spindle of the machine tool, enabling the tool to rotate precisely and engage with the surface of the workpiece. During the machining process, the machine controls the tool's rotation speed, feed rate, and feed direction to create the desired groove shape. Tools like slotting and slitting saws are capable of cutting through hard materials effectively, and the high rigidity of the slotting cutter holder ensures stability during the process.

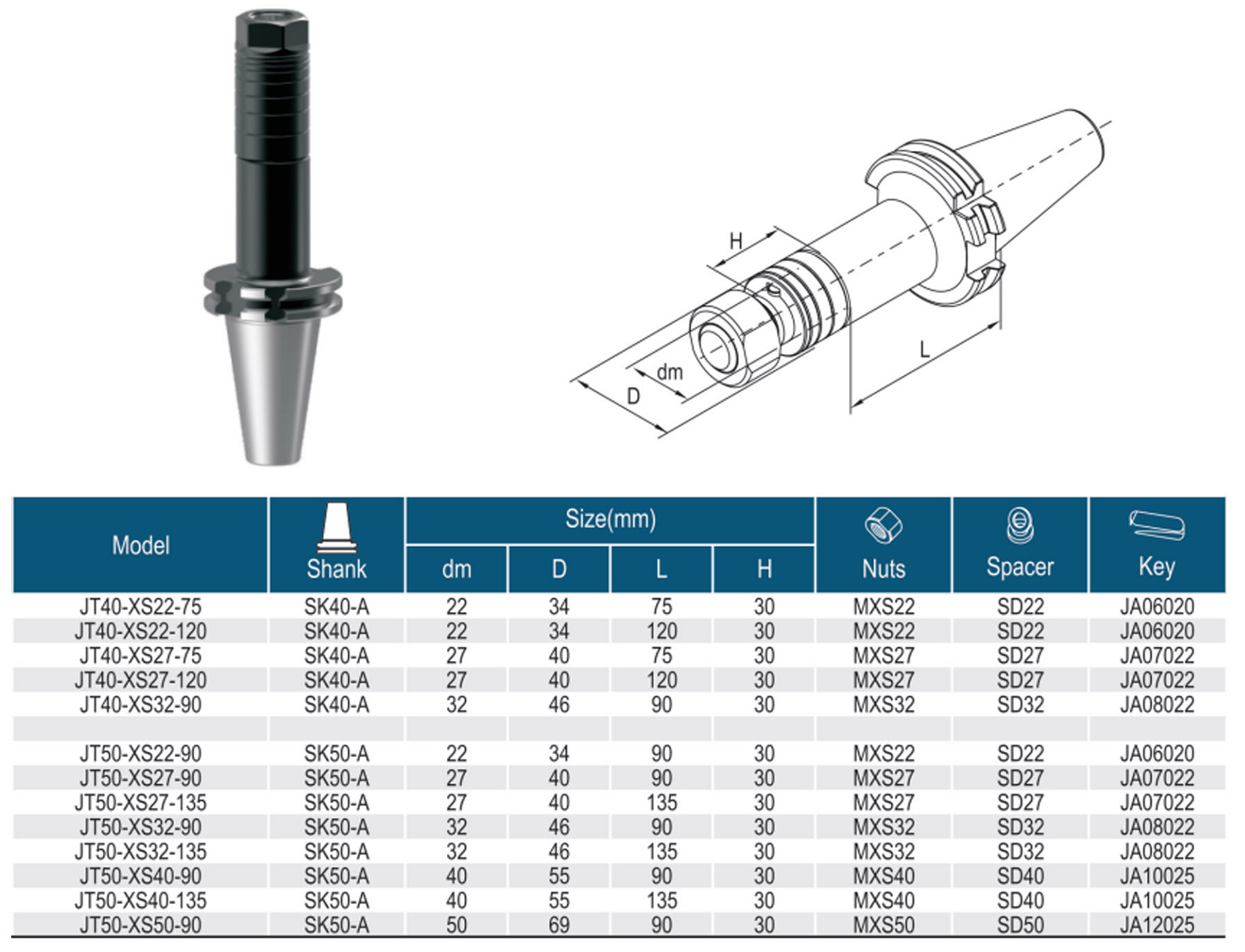

The structural design of the holder typically includes a conical or flat clamping section, such as using BT shank or other standard tool holders to connect to the machine spindle. The BT shank provides high stability through precise tapered contact, reducing vibrations during machining and thus improving surface finish and machining accuracy. The holder is also capable of handling large cutting forces when used with gear milling cutters and side-and-face milling cutters, ensuring precise relative movement between the tool and the workpiece.

Advantages

The versatility of the slotting cutter holder lies in its ability to hold various types of milling cutters and adapt to different machining needs. Whether slotting saws are used for deep groove cutting, slitting saws for thin-slot division, or gear milling cutters and side-and-face cutters for complex multi-surface cutting, the holder provides sufficient support to ensure efficiency and precision in the machining process.

Moreover, the holder is durable and has excellent vibration-damping properties, especially in high-stress machining environments. Its material and design allow it to maintain stable machining performance for extended periods, reduce tool wear, and extend tool life. This is particularly important in industrial environments that require continuous long-term machining.

Contact: Jason Lee

Email: jason@wayleading.com

Post time: Sep-27-2024